Aluminium

windows

design, comfort,

safety and durability

NorDan Aluminium windows are distinguished by Scandinavian design, ease of operation, large possible dimensions, safety and durability. Products are developed to withstand the harshest climate conditions, meet Passive standard energy requirements and easy installation.

With a goal to reduce CO2 emisions, for windows we are using aluminium profiles based on Hydro REDUXA technology, production on hydropower. This means a reduction of CO2 by 50% compared to CO2 levels of standard aluminium production in Europe.

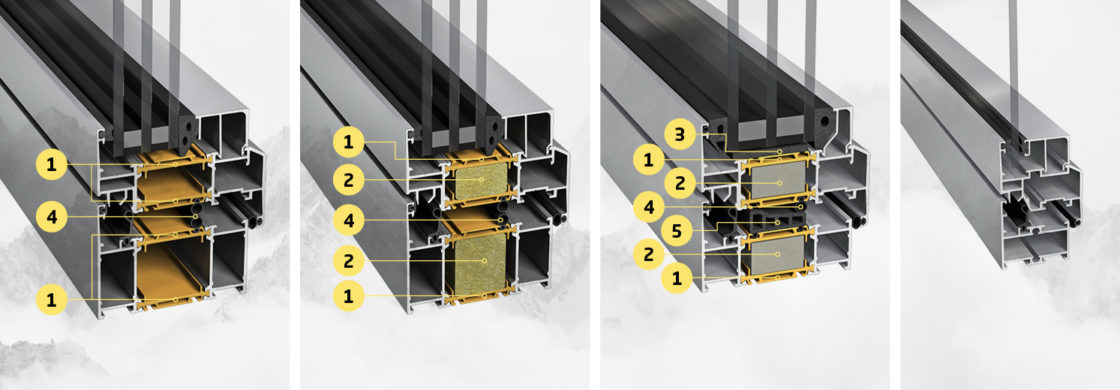

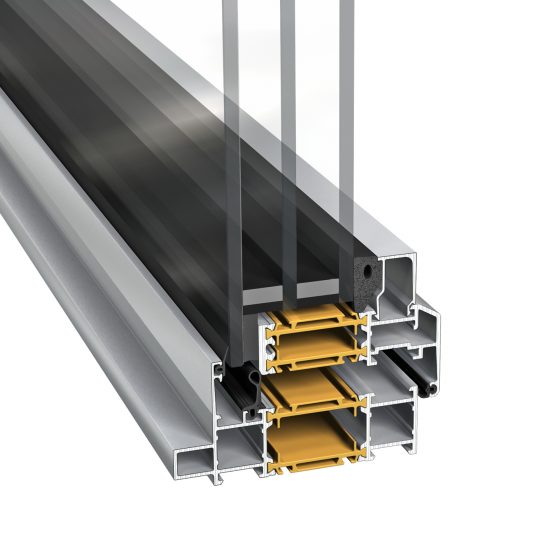

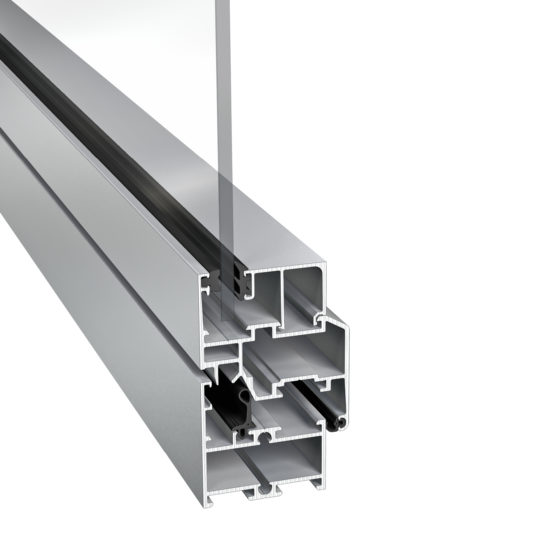

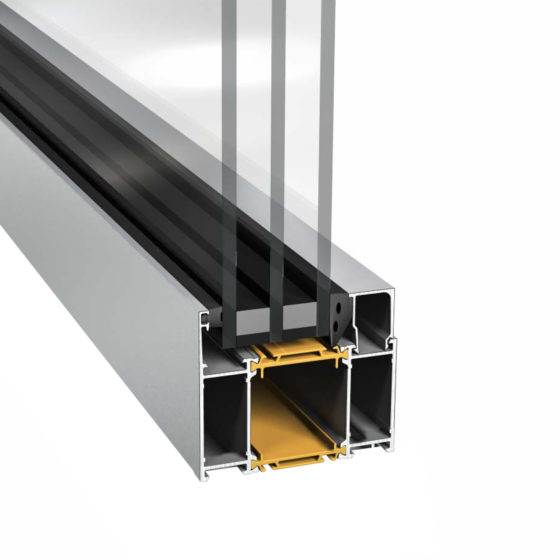

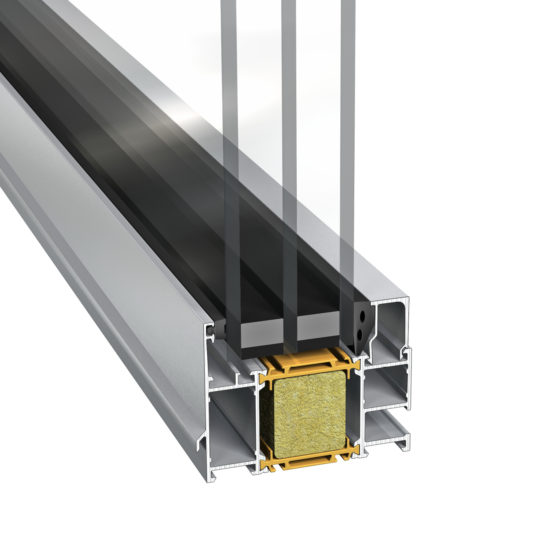

Levels of insulation

Our aluminium window solutions are available in different levels of insulation up to 0,7: basic, SX (super), PX (extra) or non-insulated systems that are suitable for interiors to meet any requirements of the building.

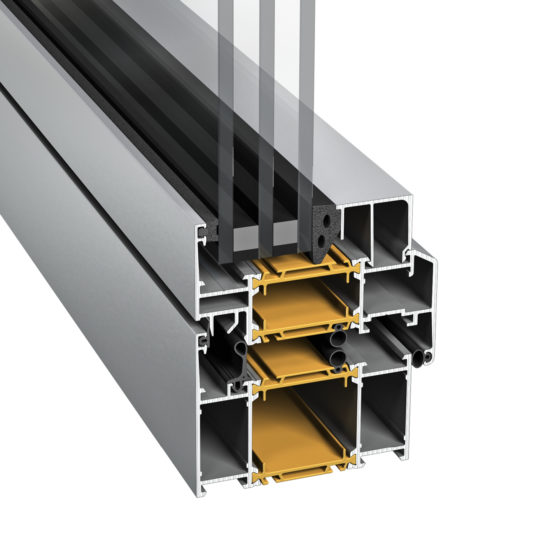

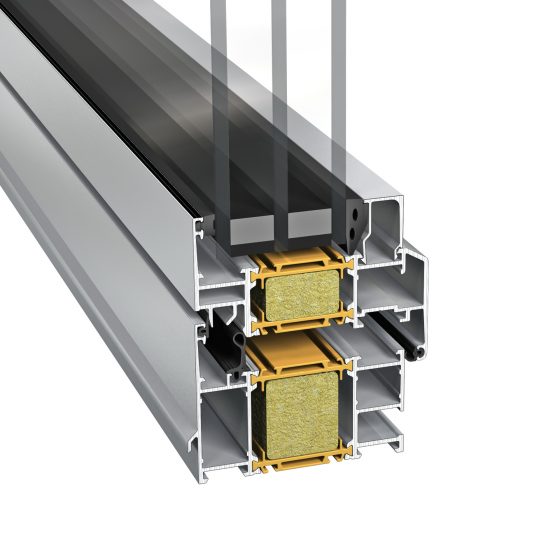

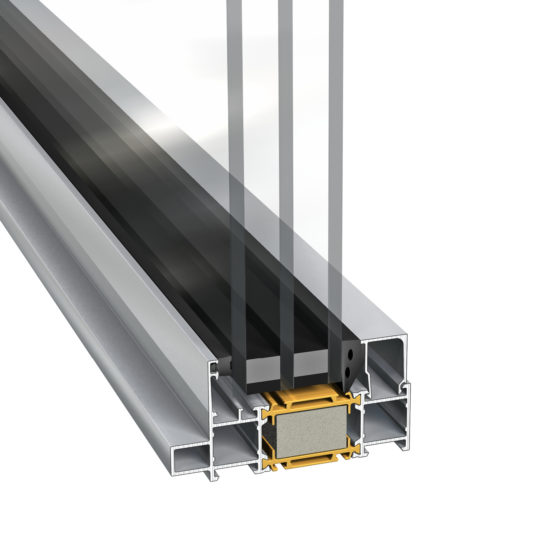

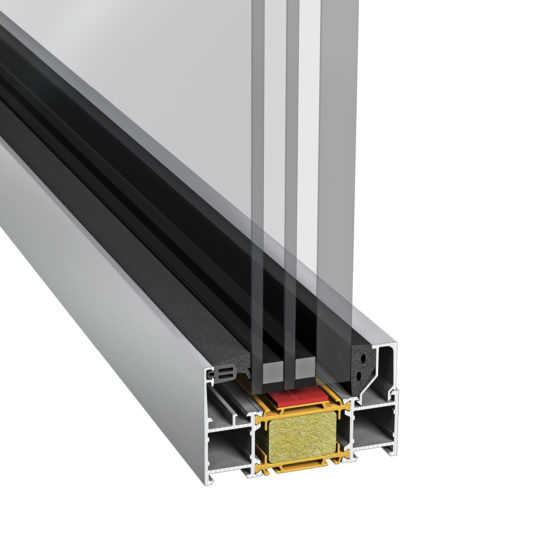

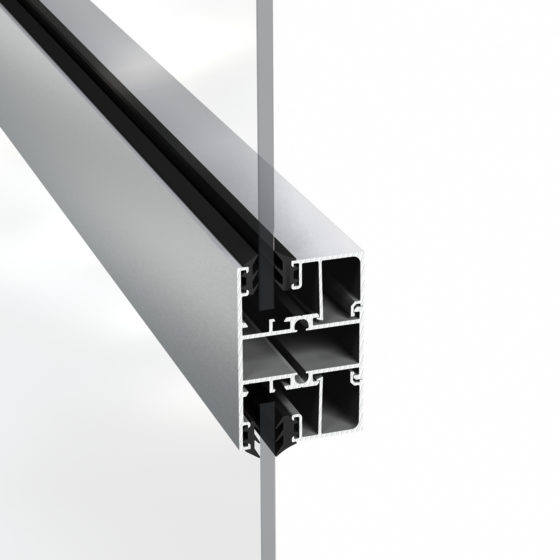

This is how the profile is built up:

- Insulating stage of fiberglass reinforced polyamide that breaks the cold bridge in the aluminum profile.

- Insulation material inside the profile: PX (polyurethane) or SX (Sapa Thermo N9).

- Insulation strip between profile and glass.

- Rebate gaskets as convection limiters.

- Extra convection barrier on the frame.

Range and design

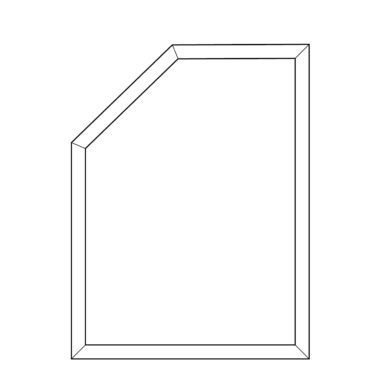

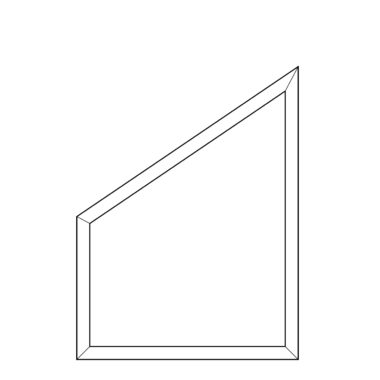

When it comes to design freedom, aluminium is the material of choice. Non-standard shapes, large dimensions, different surface treatments and unlimited choice of colors can be designed to satisfy individual requirement.

Our range consists of a wide choice of inside opening, combination, fixed windows and fire resistant systems up to EI60 class, based on 86 mm depth profiles. Non-insulated systems of 50 mm depths are suitable for interiors.

Solid and durable

Solid-looking, durable and long service life – the benefits of aluminium windows and doors that are produced to last. According to researches, aluminium products can last up to 75 years, considering propper maintenace and some of components replacement.

High quality fittings provide excellent efortless function and excellent tightness: water tightness, air permeability, resistance to wind load.

Surface finishings

Anodized surface

Anodised finish in general is the most durable choice of surface treatments available for aluminium profiles. It emphasizes the natural beauty of aluminium material, strengthens the surface and makes it resistant to UV rays and to environment exposure. Different anodized colours are possible on the inside and outside, also combined colors with powder painting for insulated systems.

Powder painting

We can produce in any colors from RAL or NCS palette. The standard surface glossness is 30%, but it is possible to choose 70%. Different colours are possible on inside and outside also combined colors with anodized colors for insulated systems.

All products undergo high-quality powder coating or anodization surface treatment.

Factory assembled

We put in the extra effort to assemble the complete product at the factory: all accessories, glass units and other ironmongery are in place, so nothing gets lost, so it would be easy to install and would save time at a construction site.

Save time at a construction site

1. The products are supplied glazed from factory.

2. Handles are mounted from factory.

3. Internal groove and outside groove are optional.

4. All fittings are factory-installed, choose between hidden or visible fittings.

5. Glass strips and sealing strips are supplied mounted.

6. Arrive with selected mounting method: pre-mounted Adjufixes or brackets.

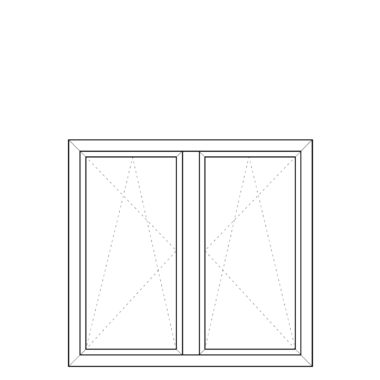

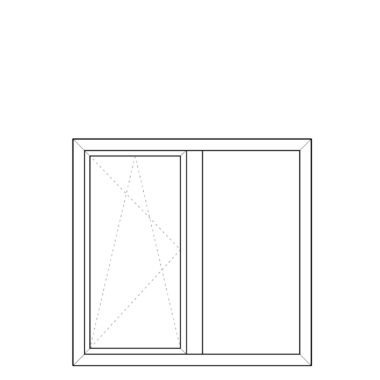

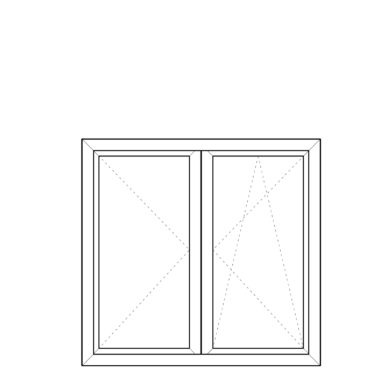

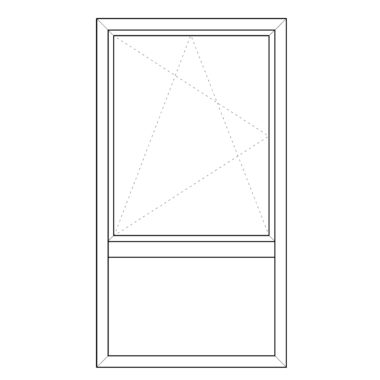

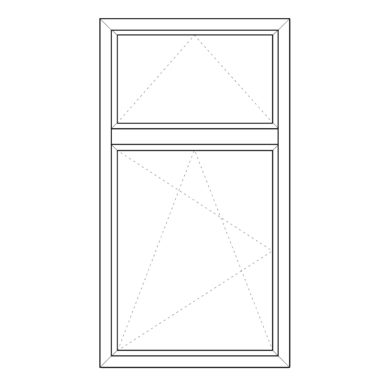

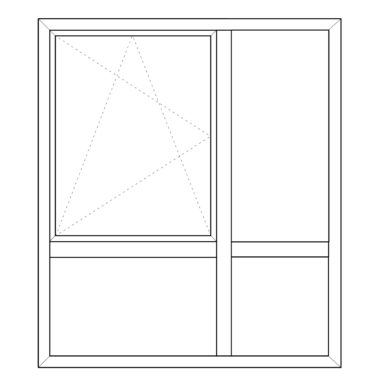

Windows configurations

Fixed frame

Kipp

Tilt before Turn (TBT)

TBT+TBT

TBT + fixed frame

Escape

TBT over fixed frame

Kipp over TBT

TBT in combination with fixed frame

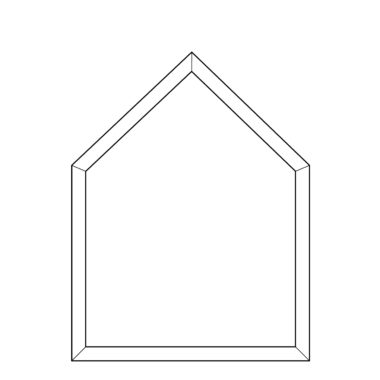

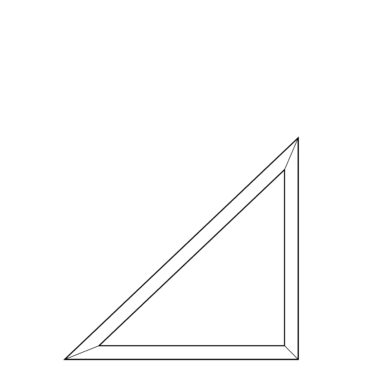

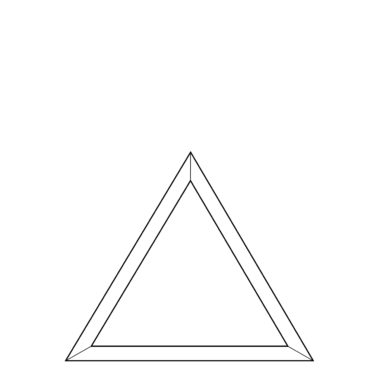

Examples of fixed frame shapes

Openable window systems

Standard

Norwegian frame

Project solution

non-insulated

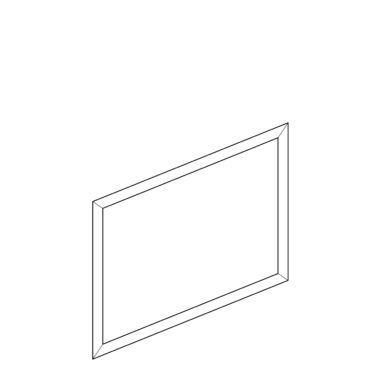

Fixed frame windows systems

Standard

Norwegian frame

Project solution

Fire resistant EI30/EI60

non-insulated